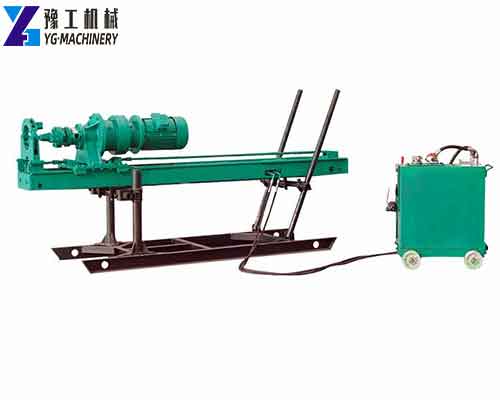

The anchor drilling rig, also known as the anchor rig, is a rigging tool in the bolt support work of the coal mine roadway. It has outstanding advantages in improving support effect, reducing support cost, accelerating speed of lane formation, reducing auxiliary transportation volume, reducing labor intensity, and improving utilization of roadway section. The anchor drilling rig is the key equipment for bolt support. It affects the quality of the bolt support orientation of the bolt hole, the depth, the accuracy of the aperture, and the quality of the bolt installation, as well as the operator’s personal safety, labor intensity, and working conditions. Moreover, we also have other types of drilling rigs, such as small water well-drilling rigs, hydraulic core drill machines, trailer water well-drilling rigs, DTH drilling rigs, gasoline rock drill machines, rotary drilling rigs, horizontal directional drilling rigs, diamond core drill machines, backpack core drill machines. Contact us now!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Anchor Drilling Rig Parameters

|

Model |

YG–MG40 |

YG–MG50 |

YG–MG70 |

|

Hole depth(m) |

10-60 |

25-70 |

35-80 |

|

Hole diameter(mm) |

90-180 |

90-165 |

90-200 |

|

Rod spec(mm) |

Φ76*1500 |

Φ76*1500/ |

Φ76*1500/ |

|

Hole angle |

0-90° |

0-90° |

0-90° |

|

Output rotary speed(rpm) |

90 |

70 |

70 |

|

Rated output torque(N*m) |

2400 |

2500 |

3900 |

|

Powerhead max stroke(mm) |

1800 |

1800 |

1800 |

|

Max lifting force(KN) |

25 |

30 |

35 |

|

Powerhead max feeding force(KN) |

20 |

25 |

25 |

|

Hydraulic system-rated pressure(Mpa) |

16 |

17-18 |

17-18 |

|

Rotary electric power |

4-pole/7.5kw |

Hydraulic |

Hydraulic |

|

Oil pump electric power(kW) |

4 |

22 |

22 |

|

Electric voltage |

380v |

380v |

380v |

|

Weight(kg) |

1000 |

1260 |

1460 |

|

Hydraulic station dimension(mm) |

640*600*580 |

1850*780*1360 |

1850*810*1280 |

|

Dimension(mm) |

2800*800*1400 |

3000*780*1360 |

3100*1000*1500 |

Anchor Drill Machine 4 Features:

- Three-phase asynchronous motor and dual-connected gear oil pump power the drilling rig.

- Adopting hydraulic cylinder feeding mode, compact structure, large lifting force, and good stability.

- The radiator can effectively reduce the oil temperature and prevent hydraulic oil from becoming low viscosity or damaged due to excessive oil temperature.

- The upper and lower hydraulic cylinders can quickly adjust the angle of the guide rail to meet the drilling requirements from different angles.

Anchor Drilling Rig Safety Check:

- It is necessary to check whether the mechanical parts of the equipment are normal and have defects.

- Check whether the control switches, handles, and knobs are complete, sensitive, and reliable, with or without defects.

- Check the screws of each part for looseness or defects.

- Check whether the various channels, accessories, etc. Used for welding meets the requirements for use.

- Check that the safety guard is safe and has no defect.

- Check whether the connections of various values and pipes are tight and if there is no leakage.

- Prepare the tools, workpieces, etc. To be used and check if they meet the requirements for use.

- Check all obstacles on the job site that have no impact on the job.

- Check whether dangerous materials such as pumice stones and umbrellas are cleaned on the upper surface of the work surface.

Anchor Drilling Rig Safe Operation:

- According to the work requirements, clear the location of the rig and the standing position of the staff (or set up the scaffolding platform) to park the rig smoothly and securely.

- When the rig is started, the driving signal must be issued first, and the operators should contact each other well to make a call response.

- Before the wind is supplied, the air duct must be bundled with the drill, air compressor, or other fixed objects.

- During the operation, a special person must be in charge of the command. All operators must concentrate on the movement, and all parts of the body should be away from the rotating parts of the equipment. Pay attention to the observation and find abnormal parking immediately.

- All kinds of tools, such as drill rods to be installed or disassembled, must be placed safely in a designed safe place to prevent falling, rolling, and affecting work.

- When installing or disassembling other workpieces such as drill rods, the tool used must be placed in a stable position, and the operation is slow. Excessive force is forbidden to prevent falling off.

- When drilling, it is necessary to control the advancement speed of the drilling rig, prohibit excessive pushing, pay attention to the observation of the working surface, and prohibit the operator from leaving the post without authorization.

- When the wall thickness of the drill pipe impactor is less than 3/5, it is forbidden to use it to prevent injury or damage to the equipment during operation.

- Night work must be well-lit.

- It is forbidden to work in strong winds and heavy rains.

- It is forbidden to crush the main air duct by various vehicles or equipment.

- When the working area of the rig is less than 3 meters from the edge of the face, specific detailed, and reliable safety precautions must be specified. The operator is prohibited from facing the edge of the face.

- When moving the device, the obstacle must be removed to make the ground flat, keep the balance of the fuselage, and pay attention to the spare parts falling.

- When pulling and moving the rig, the distance between the main body and various high and low-voltage lines shall not be less than 1.5 meters.

- When transporting equipment for long distances, the equipment must be fixed firmly with the ropes. It is forbidden to take any personnel in the vehicle compartment.

- When using lifting equipment, special personnel must be in charge of command and supervision, select the ropes that meet the requirements, and carry out the sticking according to the regulations. It is forbidden to work, pass, or stay under lifting objects.

Anchor Drilling Rig Manufactures – YG Machinery

Henan YG Machinery Co., Ltd is located in Zhengzhou, Henan province, China. It’s a large engineering machinery manufacturing enterprise that focuses on research and development, production, and sale of kinds of drilling rigs. Our drilling rigs are widely applicable for water wells, farm irrigation, geological prospecting, small pile foundations, geothermal air conditioners, and so on.

We insist on the strategy of technology research and development. technical design, material purchasing, precise manufacturing, and strict quality inspection are all processed according to the ISO9001 standard. Sincerely hope we can establish a close, trustworthy, and long-term relationship with each customer. Any interested and need about our drilling rigs, please contact us.