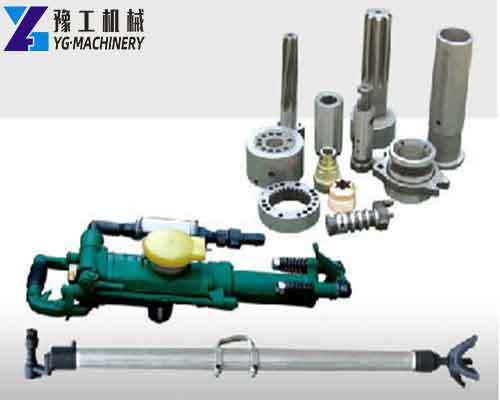

A pneumatic rock drill is a kind of percussive drilling machine powered by compressed air. According to the propulsion mode, the equipment can be divided into handheld rock drilling equipment, air leg rock drilling, telescopic upward rock drill, and guide rail rock drilling machine. A pneumatic rock drill drives the piston forward in the cylinder with compressed air, which makes the drill bit hit the rock. With the advantages of simple structure, easy operation, and low price, the pneumatic rock drilling machine is the most widely used rock drilling machine. As a reliable rock drilling machine manufacturer, the pneumatic rock drill for sale in our company is of high quality and we can also guarantee to give every customer the most competitive price. If pneumatic rock drills cannot meet your needs, we also sell gasoline rock drills, electric rock drills, pneumatic air picks, etc. For more information, please contact us.【Whatsapp/WeChat/Phone/Skype】+86 136 1385 6800

Technical Parameter of Pneumatic Rock Drill for Sale

| Model | YT28 |

| Opening hole diameter | 28-42mm |

| Drilling hole depth | 0.5-6m |

| Cylinder bore | 80mm/60mm |

| Pipe diameter | 13mm/25mm |

| Water pressure | 0.2-0.4mpa |

| Wind pressure | 0.4-0.63mpa |

| Impact frequency | ≧37Hz |

| Size | 661*247*195mm |

| Weight | 28kg |

Four Types of Pneumatic Rock Drilling Machine

Hand-Held Rock Drilling Equipment

Some pneumatic rock drilling equipment needs someone to hold them during operation, we always call this kind of pneumatic rock drill the handheld rock drilling machine. This type of rock drilling machine is lighter in weight, which is suitable for a variety of small diameter and shallow blast holes. It is generally used to hit downward holes and horizontal holes. However, it mainly relies on manual operation. So the labor intensity is high, impact energy and torque are low and the rock drilling speed is high.

Air Leg Rock Drilling Machine

The air leg rock drilling machine is a kind of equipment that installs the pneumatic rock drill on the air leg for operation. The airleg can support and propel, which reduces the labor intensity of the operator and make the drilling efficiency much higher. This type can drill both horizontal blast holes and blast holes with a certain angle of inclination, which is widely used in mines.

Telescopic upward rock drilling Machine

The pneumatic leg of the telescopic drill is on the same longitudinal axis as the main engine, which is usually used to drill upward holes, mainly for quarry and patio drilling operations.

Rail Types Rock Drill

This machine is heavy in weight and is usually installed on the guide rail of a rock drilling rig. It can drill horizontal and blast holes in all directions.

The Use of Pneumatic Rock Drilling Equipment

- Please keep the compressed air at the air inlet of the pneumatic rock drill to dry. The wind pressure should be kept at 500kPa and the minimum wind pressure shouldn’t be lower than 400kPa. Please use soft clean water. When acid or alkaline water has to be used, the lubricating oil should be injected into the rock drill immediately after the completion of the work, then turn off the water and run the machine for a while.

- If the machine is new, please clean and reassemble it first. And check if the operation is normal after installation. The idle running time shall not exceed two to three minutes. If the time is too long, the temperature of the cylinder area will be too high, which may produce the phenomenon of cylinder grinding.

- Clean the pipeline and carry out routine disassembly and overhaul regularly. Keep the machine in good working condition and add lubricating oil in time. It is strictly forbidden to work without oil.

- When operating the machine, please open the wind first and then open the water, turn off the water first and then turn off the wind. The water pressure should be lower than wind pressure, which can prevent the water from flowing back inside the cylinder of the rock drill, destroying the normal lubrication of the machine and affecting the normal operation of the machine.

- When the rock drilling machine is slow to rotate, please reduce the axial force of the air leg through the pressure regulating valve immediately. If the drill rod doesn’t turn and reducing the axial thrust of the air leg is invalid, the drilling operation should be stopped immediately. Remove the fault before starting the operation.

- Observe the powder discharge of the machine frequently, the air leg rock drilling equipment isn’t allowed to remove the water needle when while the machine is in operation.

- After the work is finished, close the water valve to let the drill machine run empty for a short time with the small wind to remove water, which can prevent corrosion.

- When the telescopic rock drill is working upwards, be careful not to let the magma flowing down the drill pipe be closed to the drill sleeve. The spacing shall be at least 20mm, otherwise, that is because the purge force is insufficient. Operators should check whether the blowhole on the drill sleeve is smooth.

- When the rock drill equipment won’t be used for a long time, disassemble and clean the device in time and coat it with anti-rust oil. Then put it in a dry place to preserve.