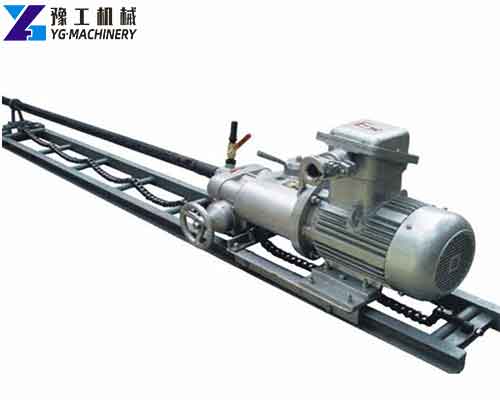

Electric rock drill rigs are also called rock drills for hitting soil layers. Foundation pits are used for roadbed soil layer anchor holes. They are often used for water conservancy construction, road construction, and stonework operations, and can also apply to gas(methane) or drilling and water exploration and gas exploration in mines where coal dust explosion is dangerous. The electric rock drill machine can be divided into engineering and mining( explosion-proof motor).

The electric rock drill is the abbreviation of the multi-function rotary electric rock drill. It is a kind of engineering rock-drilling machinery. It is now used in many fields and becomes a multifunctional engineering drilling tool. The price of rock drills is moderate, and suitable for small drilling projects, especially in small spaces, such as deep mines, road construction, and other environments, which can be easily moved, blast holes, or grout holes. Depending on the engineering requirements, it is important to choose the right rig. If you have any questions or unsolvable drilling problems in the engineering reaming operation, we have pneumatic rock drills and gasoline rock drills to meet your requirements. you can contact us.【Whatsapp/Wechat/Phone/Skype】+86 136 1385 6800

Parameter of YG Electric Rock Drill:

| Motor Power | 3Kw |

| Voltage | 380V |

| Frequency | 50HZ |

| Rotation Speed | 1420r/min |

| Motor Phase | 3 phases |

| Drilling Speed | 320mm/min |

| Drilling Diameter | 36-45mm |

| Drilling Depth | 8-15m |

| Application rock hardness | F<10 |

| Weight | 75kg |

| Dimension | 720*378*436mm |

Electric Rock Drill Application Features:

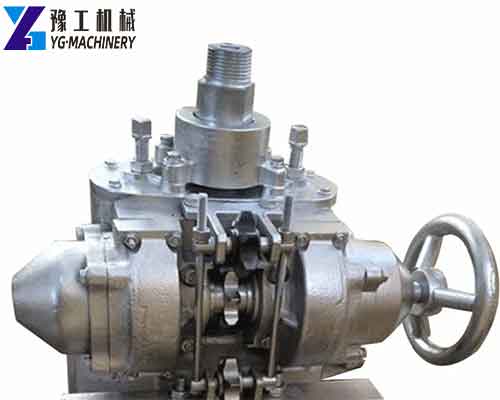

- When the rig is working, you only need to operate the handwheel to quickly advance and return.

- The rock drilling rig can drill in any direction horizontally, upwards, and downwards.

- The drilling machine can use both dry and wet drainage methods, and the water hole and air compressor are used for drilling.

- Rock drilling rigs have many fields of application and can realize rock drilling work on coal seams, rock layers, and soil layers.

Advantages:

- Explosion-proof.

- Lightweight, suitable for small space operations.

- The punch does not require an air compressor.

- Soil layers can be hit.

Operation Method:

- Rock drills require the use of drill stands and cans, which can be drilled in any direction, drilling horizontally or diagonally.

- In order to extend the service life of the drill bit, wet powder spraying or dry powder spraying (drilling with an auger) can be used during the operation.

- When the rig is working, just operate the handwheel and the rig can propel itself.

Instructions Before Use:

After purchasing a new rock drill, please read the random instructions to get an overview of the rock drill and how to use it. The maintenance of the rig is an important part. Proper operation of the rig will greatly help to extend its life of the rig. The newly purchased rig needs to be connected to the power supply, chained, and placed on the runway, so that the simple operation can be the normal operation of the rig. When using, it is necessary to stabilize the drilling machine as much as possible to maintain the stability of the overall drilling machine, which is conducive to the high-precision reaming diameter. When the drill pipe is used in conjunction, the drill pipe joint is matched to keep the drill pipe joint seamless and close, so as to increase the drilling depth.

How to Use and Precautions:

- Determine the erection position of the rig (homemade) according to the use occasion and the position of the drill hole.

- Install the chain on the mainframe first, then install the mainframe on the runway, connect the two ends of the chain to the runway, adjust the chain tie rods to obtain a certain tension for the chain, and then fix the runway to the drill stand.

- Turn the handwheel to the neutral position before drilling, and run for 5 minutes at no load. When the motor is well insulated, the rock drill has no abnormal sound, and the direction of rotation of the main shaft coincides with the direction of the arrow on the reducer, then the drill pipe and the drill pipe are installed. Switch on the water source.

- When opening the hole, slowly rotate the handwheel in the direction of the arrow and gently connect the clutch. When the bit body is fully drilled into the rock, forcing the clutch tightly, the force should not be too strong. When drilling to the required depth, you should quickly turn the handwheel in the opposite direction to stop the advance. Press the arrow again to tighten the clutch, and the main machine will quickly retract. Wait until the drill bit completely exits the hole and stop drilling. Otherwise, the drill bit and parts will be damaged. At this time, the handwheel will be turned to a neutral position.

- During the drilling process, if the drill pipe is bent or stuck, the drill should be drilled off immediately to check whether the drill bit is sharpened or disintegrated, whether it encounters a hard fault, or whether the voltage at the incoming end of the motor meets the rated voltage. If it is lower than the rated value, it must be adjusted to the rated value.

- It is strictly forbidden to dry the eyes, strictly implement the method of first water supply, then open the drill, and stop the water after stopping the drill first. Pay attention to the water supply during drilling. In case of a sudden water stop, the drill must be stopped immediately, so that the drill bit can leave the bottom of the hole in time to prevent the drill bit from clogging and a stuck drill accident.

- If the rock drill has an abnormal sound, it should be checked and repaired immediately. The gearbox should be cleaned and replaced regularly, and the motor should be dried regularly if necessary.