The blast hole drilling machine is a rotary impact drill. It can also be called a DTH drilling rig. The impactor is directly submerged into the bottom of the hole to drill the rock, the transmission loss of impact energy is small, and the drilling efficiency is high. Blasthole drilling machine can be used for drilling rock anchor cable holes, anchor holes, blast holes, grouting holes, and other drilling constructions in urban construction, railway, highway, river, hydropower, and other projects.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

YGL100A Blast Hole Drilling Machine

Feature:

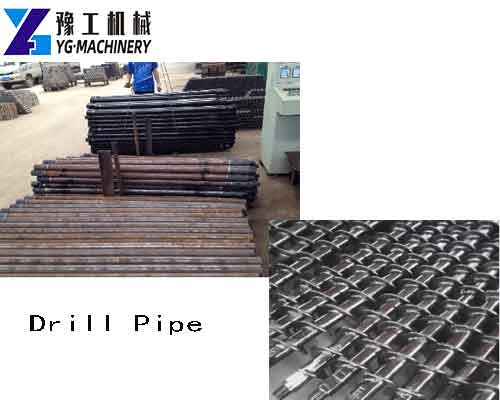

- Portable drill pipe rack, reducing the time and cost of workers.

- The whole machine operation platform is suitable for a single person and single machine operation, which is convenient for observing the progress of drilling.

- The whole machine is equipped with a sleeve roller chain, fixed pulley, and movable pulley driven by a sprocket, which improves practicability and durability.

- The pressure gauge in the instrument panel can quickly diagnose the fault of the drill carriage.

- The walking part is equipped with a 0.5s reinforced walking motor, replacing the original 1.6s steel ball motor.

- The power head-turning motor is improved from the original 700 pendulum cylinder motor to a high-speed cycloid BM630 motor.

| Model | YGL100T | YG130 |

| Apply rock | 6-20 | 6-20 |

| Drilling depth | 30m | 30m |

| Drilling diameter | 90-130mm | 90-130mm |

| Power type | diesel | diesel and electric |

| Traveling speed | 2.5km/h | 2.5km/h |

| Highest horizontal hole | 2.8m | 2.8m |

| Lowest horizontal hole | 0.3m | 2.3m |

| Dimension | 4400X1980X2260mm | 4250X1980X2260mm |

| weight | 3.5t | 3.8t |

YG150 Blast Hole Drilling Machine

YG150 drill rig is a new type of drill rig independently developed and produced by our company on the classic model 150T. This rig has been continuously tested and improved by the company’s technical team to improve stability while reducing costs improve work efficiency and achieve drilling rigs with medium and high wind pressure drilling operations, with super high-cost performance, widely used in mining blasting, urban foundation pit construction, highway construction, hydropower, and other engineering projects.

YG180 Blast Hole Drilling Machine

The YG180 drilling rig is a high-wind pressure model produced by YG Machinery Co., Ltd. It is specially designed for quarries with chassis floating cylinders and side guide rails, facing hard rock formations such as granite and basalt. It is equipped with high wind pressure drilling tools as standard, which is robust the walking mechanism can rope with a variety of complex terrain. Equipped with a two-stage dry dust collector, which can meet the environmental protection requirements of all mines and achieve dust-free operation. Products are widely used in various types of engineering construction and mining. Products with high efficiency, energy saving, environmental protection, and safety are widely selected by modern green mines.

YG300 Blast Hole Drilling Rig

YGM150T and YGM153T Drilling Rigs Feature:

- Individualized and humanized design, strong structural strength, beautiful appearance, convenient operation, and maintenance. The hydraulic system is designed to absorb and digest domestic and foreign experiences.

- The vehicle’s diesel engine insists on using well-known domestic brands, adopts the most reliable intake filter system to ensure the safety of diesel engine intake, and the hydraulic components use the most stable domestic brand products to impress customers with quality and win customers with word of mouth.

- The raw materials of the whole vehicle are selected from domestic high-grade steel plates, wires, profiles, and other steel, and safety and quality are the prerequisites for conscience products.

- The hydraulic system has been improved and improved from the hydraulic valve and the hydraulic hose to the needs of the actual working conditions. The high system pressure effectively improves the adaptability of these two rigs to complex working conditions.

- The powerhead is flexible in configuration. The standard configuration is a large-displacement and high-torque cycloidal motor. It can also be driven by a dual hydraulic motor on-site according to customer needs.

- The special design of the joint of the drill arm can realize the guide rail perpendicular to the drill arm, which is suitable for drilling under special conditions. Horizontal holes can be drilled at different heights from 350mm to 3600mm by adjusting the hydraulic oil cylinder.

- The diesel-electric dual-use drilling rig adopts a diesel engine + electric motor hybrid power. Customers can choose any one of the powers according to their needs. The hydraulic system is automatically switched without manual adjustment.

Dust Collector

With the country’s protection of the environment and meeting the requirements of environmental protection in mines, our company’s crawler truck series can optionally be equipped with dust collectors.

The dust collector has a primary filter and a secondary filter. The first filter system removes; large particles of dust. The second filter will filter out the fine particles of dust through the filter element.

The duct collector is powered by an engine or an electric motor. A gear oil pump is installed at the steering power pump of the diesel engine to provide hydraulic power. The fan is driven by hydraulic power to drive the motor (plunger motor) to achieve the suction effect. The filter element in the dust collector plays a role in filtering dust.